3D printing has been available since 1980’s but it took the post-PC revolution and Internet of Things to commercialise the genre and turn it from an industrial technology‚ to something that can be used at home. Since the launch of recent consumer 3D printers‚ we have seen some amazing replication of designs and items‚ that until now could only be visualised on computer screens. This demand has fuelled the growth of a few companies producing consumer-grade 3D printers like ProtoMaker‚ MakerBot‚ and Cubify.

While the current focus of hobbyists is primarily crafting interesting but niche items like abstract and geometric designs‚ the potential for 3D printing to transform the retail & manufacturing industries is hugely disruptive and exciting. Sectors like healthcare are seeing innovation where companies are working on printing human body parts that can replace prosthetics that are very expensive and difficult to manufacture. We are even looking at a grocery revolution thanks to the concept of 3D printed food with the assistance of devices like the Foodini (if you can excuse the terrible name).

Opportunities

Is it inevitable that the future of retail & commerce will now involve us heading to digital blueprint stores like MakerBot Digital Store to buy our next piece of crockery‚ mug‚ or desk lamp? How long will it be before retailers are seriously having to consider 3D printing as part of their retail mobile strategy?

It’s difficult to say‚ but we think 3D printing has the potential to usher in an exciting era of truly personalised products moving from factories generating mass replica products to millions of people grabbing a base design or blueprint that they can customise to their own tastes and likes.

Social networks like Thingverse will start enabling crowdsourced designs which will open up the potential for new & interesting products to be designed. What happens when we truly democratise the design of products where anyone can produce a quick prototype in their study without having to invest millions in the traditional tooling and factory manufacturing processes? New product development & design that was previously restricted to large enterprises with significant R&D capital and facilities due to the risk involved in producing prototypes of physical products will now be accessible to everyone. This will usher in a new era of exciting start-ups that can move faster than the larger enterprises while rapidly iterating and innovating on designs. It creates a truly level playing field for start-ups producing physical products to get their ideas to the market quicker than it is possible.

What does this also mean for our high street and e-commerce stores like Amazon? While we might still need our local IKEA & car dealer for sourcing large items that are unlikely to be easily printable at home‚ retailers that primarily rely on selling smaller sized household items will either have to rapidly innovate to discuss this market or simply die. While this certainly won’t happen in the next decade or two‚ it is a very real possibility that the next century will bring disruption at a massive consumer scale.

3D printing might also be a huge boon for the environment with a renewed focus on recycling and repurposing of printed objects. Consumers could potentially complete the entire recycling process at home and not put everything in a bin and hope it helps the environment. It also paints a great future for repurposing existing equipment you have in your house. Have no further use for that cup you made a couple of years ago? Reuse the material to make yourself a lamp or a utensil. Of course‚ recycling is not a trivial process due to the materials used today but we will start to see innovation in materials that can be broken down and re-made into other complex objects.

Challenges

One of the key challenges 3D printing at home faces is the materials that are available to consumers are limited to primarily resin or plastic like products that can be easily moulded in a 3D printer. Complex 3D printing using tougher strength materials like metal & other durable materials is still very much the domain of industrial production processes and factories.

The liberalisation of production of everyday objects also brings with it a key challenge for designers when it comes to intellectual property and issues around copyright‚ trademarks and patents. Like music‚ when the distribution method & channels were tightly controlled and uneconomical‚ it is easy for producers to keep a tight control on the product and the intellectual property behind it. However‚ once the product that you are selling is primarily digital (a blueprint or MP3) file‚ it is much more difficult to enforce control over distribution channels and check their use. While DRM technology is pretty mature and can easily address digital blueprints‚ it will face similar challenges to music privacy where obtaining a desirable product is as simply as e-mailing someone the design blueprint.

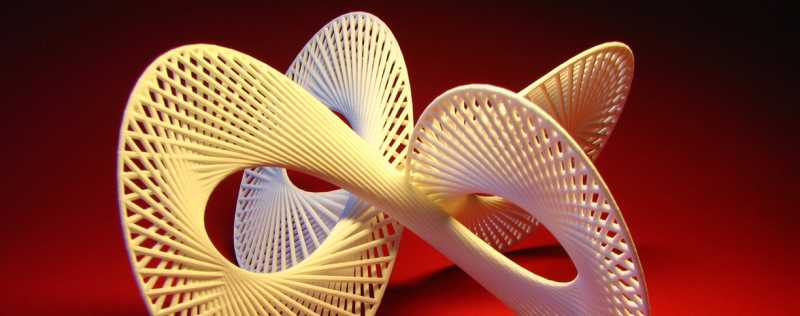

Header image © fdecomite on Flickr https://www.flickr.com/photos/fdecomite used under Creative Commons – Attribution 2.0 Generic license